DUST FILTRATION

The prevention of hazardous industrial wastes and manufacturing dynamics gain more importance nowadays where Operational Efficiency which includes the balance of efficiency, profitability and low operation costs is of equivalence with environmental consciousness and human health. Therefore, the implementation of modern filtration systems during manufacturing processes is quite significant. Emmission prevention and/or recuperation of the dust into the system as a result of the collection of the dust carried with air has reached very efficient levels thanks to modern filters. Filter fabrics that can operate under various temperatures and chemical resistance degrees have reached the level of filtering very fine dust particles by means of special chemical applications and ePTFE membrane applications. The following articles as the main purpose of filtration and many more signify the results which can be obtained by new generation filter bag fabrics. ■ The collection of the particles of the dust formed ■ The effective separation of dust from the product or as a product. ■ The minimization of the damage inflicted upon the natural balance ■ The establishment of a healthy working environment ■ The recuperation of the material of economic value back into the system

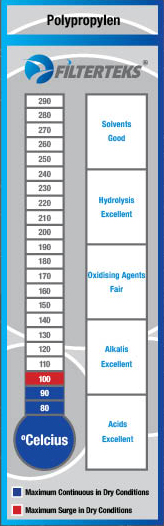

POLYPROPYLENE

Polypropylene, is a thermo-plastic polymer. Polypropylene, obtained by the conversion of monomer propylene into polymer, is highly chemical solvents (acid and base) resistant. Fabrics in the low temperature filtration felt classification can operate with high chemical and thermal resistance under dry heats up to 90°C and can operate for very long periods. These strainer felts produced from fiber are frequently used in the solid-liquid separation processes in the food, drinks and chemical sectors. There are felts available in the range of 1-200µ. Water and oil repellent features, dust collecting activity enhancer features and sparkle and fire resistant features may be achieved along with various chemical applications. For further information please check out the Chemical Applications section…

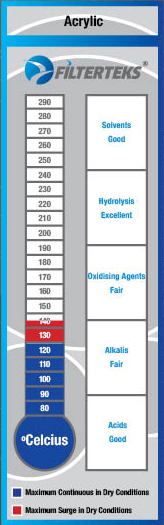

ACRYLIC

Acrylic fiber is a product of the polymerization of the acrylonitrile matter and it is, amongst the synthetic fibers, the one the most resembling wool. Acrylic fiber contains at least 85% acrylonitrile in its chemical composition. As acrylic can be used as 100%, it can also be used as a mixture with other materials. Acrylic mainly reflects homopolymer productsin industrial filtration. Use of a little co-polymer form is also possible in cases of more appropriate, less stringent conditions and conditions where prices are primary. The advanced features of homo-polymer acrylic which is fit for use in industrial processes are; ■ High resistance ■ Low gravitation ■ Perfect resistance to chemicals ■ Thermal Resistance ■ Perfect hydrolysis resistance ■ High Modulus ■ Conformity to operate under high temperatures up to 130°C You must be careful when using fiber with low strength mechanical resistance in systems where mechanical stress is intense. This mechanical weakness is seek to be overcome by the mixtures made with polyester fibers. Water and oil repelling functionality, dust collection improving functionalities and fire and sparking resistance improving functionalities may be acquired with various chemical applications. For further information please check out the Chemical Applications section… As filtration felts are insulators by nature, filtration fabrics may acquire Anti-static features with the addition of anti-static fibers and/or anti-static inner fibers. For further information please check out the Anti-Static Feature section …

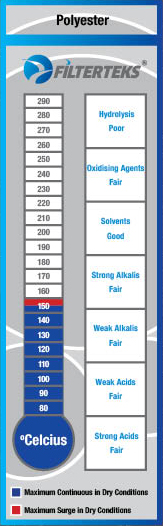

POLYESTER

Polyester is a category of synthetic polymers. With a more specific definition, it is a condensation polymer containing ester functional groups in its main bonds. Despite many polyester types, polyester means a wide synthetic polyester group of all polyethylene terephthalate and polycarbonates in general. Industrial filtration polyesters are practical in dust collection, have an effective cost ratio and are the most commonly used needle filter felts. Thanks to its chemical features, they are resistant to abrasion, can operate at temperatures up to 150°C and are quite resistant to general acids, solvents and oxidants. The only true weakness of polyester is its response to moisture. Moisture in high temperatures may cause the fibers of the polyester to dissolve and return to its main components. Water and oil repelling functionality, dust collection improving functionalities and fire and sparking resistance improving functionalities may be acquired with various chemical applications. For further information please check out the Chemical Applications section… As filtration felts are insulators by nature, filtration fabrics may acquire Anti-static features with the addition of anti-static fibers and/or anti-static inner fibers. For further information please check out the Anti-Static Feature section …

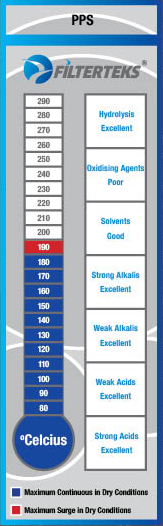

PPS

PPS (Polyphenylene Sulphide) is an organic polymer formed of aromatic rings bonded with sulphide. Synthetic fiber forms manufactured for industrial filtration are characterized with their resistance to chemical attacks and temperature. PPS is a high performance thermoplastic with industrial area of use. Shows “perfect” resistance to the hydrolysis that can be caused by moisture. In addition, they have the ability to show “perfect” resistance against chemical attacks that may be formed by acids and alkali. The existence of O2, NO2 gases and the element of bromine during the use of PPS fabrics in filtration systems has to be taken into consideration. As the existence and the rate of O2, NO2 gases at temperatures above 140°C increases, the resistance of the fabric to preserve its structure will decrease and therefore shorter filter bag life will be experienced. Water and oil repelling functionality, dust collection improving functionalities and fire and sparking resistance improving functionalities may be acquired with various chemical applications. For further information please check out the Chemical Applications section… As filtration felts are insulators by nature, filtration fabrics may acquire Anti-static features with the addition of anti-static fibers and/or anti-static inner fibers. For further information please check out the Anti-Static Feature section …

META ARAMID

The term meta aramid is the abbreviation of “aromatic polyamide”. Aramid fibers are high performance artificial synthetic fibers. The molecules of aramids are characterized with strong hydrogen bonds by solid polymer chains. They don’t melt because the aromatic structure improves the solidity of the chain. For this reason, the aramids are derived from solutions. Improved dust collection surfaces formed thanks to this non-circular structure of the fiber adds fabrics produced from meta aramids the functionality to collect more dust. Meta aramid filter fabrics have the ability to work under high temperatures (up to 220°C) due to their chemical structure. But like the other polymer in its group, it is sensitive to moisture.Loss of functionality may be experienced due to the moisture that may arise in high temperatures. Original fiber is known to be Nomex© which is manufactured by DuPont. There are many Aramid fibers today which are manufactured with similar chemical characteristics and they are called “Aramids” in general. Water and oil repelling functionality, dust collection improving functionalities and fire and sparking resistance improving functionalities may be acquired with various chemical applications. For further information please check out the Chemical Applications section… As filtration felts are insulators by nature, filtration fabrics may acquire Anti-static features with the addition of anti-static fibers and/or anti-static inner fibers. For further information please check out the Anti-Static Feature section …

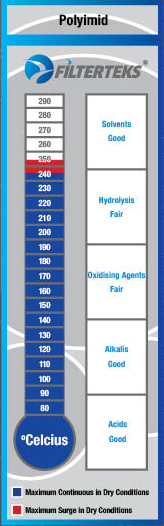

POLYIMIDE

Polyimide refers to the polymer structure of the imide monomers. Generally its Aromatic types are preferred due to their thermo-stabilities. The fiber produced by Evonik and which is also known as P84© is a high temperature fiber that can operate under dry conditions at temperatures up to 250°C. With its three-lobbed special fiber structure, it possesses a high dust collecting capacity. It has an advanced chemical and thermal resistance. The existence oxidizing gases like NO2 and moisture in high temperatures should be taken into consideration in the use of fiber whose chemical and thermal resistance values can be topped only by PTFE fabrics in the filtration felts classification. Water and oil repelling functionality, dust collection improving functionalities and fire and sparking resistance improving functionalities may be acquired with various chemical applications. For further information please check out the Chemical Applications section… As filtration felts are insulators by nature, filtration fabrics may acquire Anti-static features with the addition of anti-static fibers and/or anti-static inner fibers. For further information please check out the Anti-Static Feature section …

PTFE

Also known with the Teflon commercial name, polytetrafluoroethylene (PTFE) is a polytetrafluoroethylene that has a fluoridated ethylene polymer. It is a thermoplastic fluoropolymer. The molecular structure made up of a long and straight carbon chain saturated with fluorine atoms, has quite inert characteristics due to strong bonds between the atoms. Teflon, which is resistant to heat, chemical materials, moisture, flash over (dielectric) and friction, doesn’t adhere to any material and has the lowest friction coefficient amongst all solid materials. It is the ultimate choice of fabric in industrial filtration felts. High chemical and thermal resistance and with its almost inert structure, it can be used safely at temperatures up to 260°C.

LIQUID FILTRATION

In companies where processes to separate solid particles from liquids are required, the recovery of water used in many processes of production, treatment of liquids containing hazardous wastes generated as a result of the processes and the separation of valuable products and/or semi-finished products carried by liquids are significant both in economic wise and also in protecting the environment. Filter-presses and belt presses are preferred in the manufacturing and purification plants of enterprises for these purposes. Thanks to filter presses, companies recover water to a great extent and reduce the harm to the environment to the minimum by disposing the waste slime in the desired dryness levels. As the right choice of quality filter fabrics improve the efficiency of the purification plants, they also ensure the decrease of operating costs and the improvement of the quality of the water used. At this point, the choice of Filter Press fabric constitutes the most important point in lowering operational costs and improving efficient purification. The right and desired choice of quality filter press fabrics is at a key point in achieving these acquisitions.

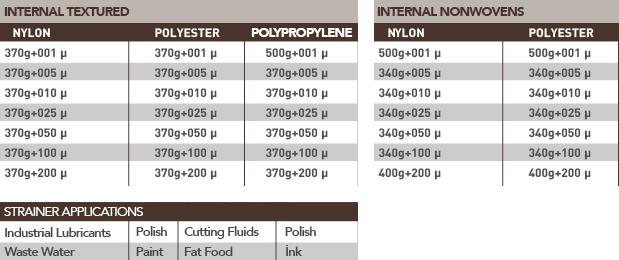

STRAINER FILTER BAGS

These bags used in the liquid filtration processes are mostly manufactured from polyester, nylon and polypropylene fabrics. Bags manufactured from aramid and other felts are amongst the range of products but their use is quite limited. This felt type that is widely used in very special filters may have special requirements according to the process that it is going to be used at. We use silicon-free and stain and defect free fabrics for food and paint sectors in order to meet environment and health norms. The products are manufactured with and without inner fibers.

FILTER-PRESS & FILTER-BELT & LAROX-BELT FABRICS

They are used with filters for special purposes such as purification, dehydration, sediment separation. They are widely manufactured from polypropylene, polyester, nylon, polyamid and cotton yarn. The resistance values characterized with the warp and weft yarn structure according to the process they are going to be used at, air permeability and weaving varieties define the desired filtration efficiency. They may be woven in Satin, Special Satin, plain, Twill types and every fabric woven differently possess different features. The correct method of weaving directly effects all system data from presscake removal to small particle collection. No less important than yarn and weaving style, calender, heat treatment etc. surface treatments also have an effect on the efficiency and the performance of the fabric. Filter-press, filter-belt and larox-belt filter fabrics have quite a vast range of products. The right choice of fabric is highly important and depends on many variables. Please request technical assistance for the selection of suitable fabrics...

FILTER-PRESS PLATES

The filter-press plates used in various filter systems provide support and mobility to the filter fabrics of solid-liquid separation. Chamber, membrane and frame/plate types provide different benefits according to the processes they are going to be used at with different features. The plates are mostly manufactured from 100% polypropylene material. The quality of the plate directly effects the plate itself and the filter fabric on it in terms of long life, endurance, abrasion resistance and high operational efficiency. Please request technical assistance for further information on plates.

AIR SLIDE FABRICS

Thanks to its know-how and field experience over the years, Filterteks® have served our industry for over 30 years with patented and own production Air Duct Slide Belts. Quality raw material usage and distinctive weaving styles, Filterteks® Air Duct Slide Belts provide long-life, perfect air-flow and cleaning convenience. Apart from the standard range of products, we produce “custom solutions” in the desired thickness and air permeability values. It is possible to weave in the desired values of air permeability and resistance in accordance with the structure of the application to be deployed. Use of Stapel and Multifilament yarns as warp and weft weaving yarns is possible in Air Duct Belts. Unless otherwise demanded, Filterteks® uses the Multifilament warp and Stapel weft weaving which are the highest quality, the most durable and the most efficient productions amongst this range of products in its own production Air Duct Slide Belts. Air duct slide belts can be manufactured to be of thickness between 4mm and 10 mm and to operate at temperatures between -60o and 300o. Belts are manufactured from Polyester (PES), Meta Aramid (MA) and Para Aramid (K) yarns. The belts may be endowed with anti-static features where applications where static electrification is a problem. Polyester (PES) Air Duct Slide Belts are highly resistant to chemicals. But win the presence of moisture, acid and alkali, their permanence decreases. They operate smoothly at temperatures up to 150o. Meta Aramid (MA) and Para Aramid (K) Air Duct Slide belts are suitable for applications operating at high temperatures. They can operate at temperatures up to 220o and 260o respectively.

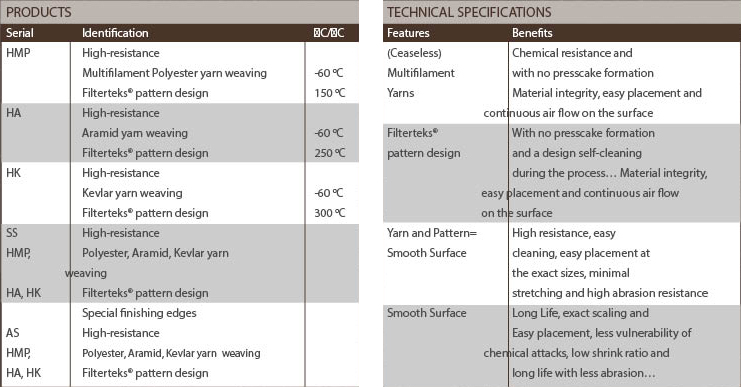

PRODUCTS AND TECHNICAL SPECIFICATIONS

AIR PERMEABILITY

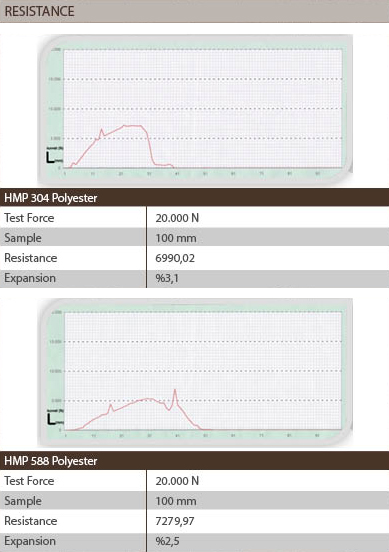

RESISTANCE

INDUSTRIAL FELTS

Filterteks provides service with its long years of experience and wide range of products for industrial felts which are manufactured from polyester, aramid, polyamid and wool fiber and their mixtures, and which are used in many machinery in various sectors like textile, laundry, ironing, leather, aluminum and food. Sanfor felts are felts used at Sanfor machines used in the processes of the sanforizing of woven fabrics manufactured in various styles. Sanfor felts may be manufactured from Aramid, Polyamid and Wool Fiber and their mixtures. These transfer felts that are widely used in the heat and pressure-aided printing machinery are usually manufactured from aramid fibers. They are also used in the ironing and lamination processes of various fabrics. Laundry felts which are special felts for laundries and which are used in many sectors are manufactured from polyester, aramid and wool fibers and their mixtures. Food sector felts offered for various chemical applications and sizes such as endless weaving and endless weaving biscuit felts are manufactured from wool fibers. Please request information and support for all kinds of industrial felt requirements of yours.

ENDLESS FELTS

Filterteks provides service with its long years of experience and wide range of products for industrial felts which are manufactured from polyester, aramid, polyamid and wool fiber and their mixtures, and which are used in many machinery in various sectors like textile, laundry, ironing, leather, aluminum and food. Sanfor felts are felts used at Sanfor machines used in the processes of the sanforizing of woven fabrics manufactured in various styles. Sanfor felts may be manufactured from Aramid, Polyamid and Wool Fiber and their mixtures. These transfer felts that are widely used in the heat and pressure-aided printing machinery are usually manufactured from aramid fibers. They are also used in the ironing and lamination processes of various fabrics. Laundry felts which are special felts for laundries and which are used in many sectors are manufactured from polyester, aramid and wool fibers and their mixtures. Food sector felts offered for various chemical applications and sizes such as endless weaving and endless weaving biscuit felts are manufactured from wool fibers. Please request information and support for all kinds of industrial felt requirements of yours.

TRANSFER AND PRINTING FELTS

Filterteks provides service with its long years of experience and wide range of products for industrial felts which are manufactured from polyester, aramid, polyamid and wool fiber and their mixtures, and which are used in many machinery in various sectors like textile, laundry, ironing, leather, aluminum and food. Sanfor felts are felts used at Sanfor machines used in the processes of the sanforizing of woven fabrics manufactured in various styles. Sanfor felts may be manufactured from Aramid, Polyamid and Wool Fiber and their mixtures. These transfer felts that are widely used in the heat and pressure-aided printing machinery are usually manufactured from aramid fibers. They are also used in the ironing and lamination processes of various fabrics. Laundry felts which are special felts for laundries and which are used in many sectors are manufactured from polyester, aramid and wool fibers and their mixtures. Food sector felts offered for various chemical applications and sizes such as endless weaving and endless weaving biscuit felts are manufactured from wool fibers. Please request information and support for all kinds of industrial felt requirements of yours.

DEKATÜR FELTS

Filterteks provides service with its long years of experience and wide range of products for industrial felts which are manufactured from polyester, aramid, polyamid and wool fiber and their mixtures, and which are used in many machinery in various sectors like textile, laundry, ironing, leather, aluminum and food. Sanfor felts are felts used at Sanfor machines used in the processes of the sanforizing of woven fabrics manufactured in various styles. Sanfor felts may be manufactured from Aramid, Polyamid and Wool Fiber and their mixtures. These transfer felts that are widely used in the heat and pressure-aided printing machinery are usually manufactured from aramid fibers. They are also used in the ironing and lamination processes of various fabrics. Laundry felts which are special felts for laundries and which are used in many sectors are manufactured from polyester, aramid and wool fibers and their mixtures. Food sector felts offered for various chemical applications and sizes such as endless weaving and endless weaving biscuit felts are manufactured from wool fibers. Please request information and support for all kinds of industrial felt requirements of yours.

SANFOR FELTS

Filterteks provides service with its long years of experience and wide range of products for industrial felts which are manufactured from polyester, aramid, polyamid and wool fiber and their mixtures, and which are used in many machinery in various sectors like textile, laundry, ironing, leather, aluminum and food. Sanfor felts are felts used at Sanfor machines used in the processes of the sanforizing of woven fabrics manufactured in various styles. Sanfor felts may be manufactured from Aramid, Polyamid and Wool Fiber and their mixtures. These transfer felts that are widely used in the heat and pressure-aided printing machinery are usually manufactured from aramid fibers. They are also used in the ironing and lamination processes of various fabrics. Laundry felts which are special felts for laundries and which are used in many sectors are manufactured from polyester, aramid and wool fibers and their mixtures. Food sector felts offered for various chemical applications and sizes such as endless weaving and endless weaving biscuit felts are manufactured from wool fibers. Please request information and support for all kinds of industrial felt requirements of yours.

MANŞON FELTS

Filterteks provides service with its long years of experience and wide range of products for industrial felts which are manufactured from polyester, aramid, polyamid and wool fiber and their mixtures, and which are used in many machinery in various sectors like textile, laundry, ironing, leather, aluminum and food. Sanfor felts are felts used at Sanfor machines used in the processes of the sanforizing of woven fabrics manufactured in various styles. Sanfor felts may be manufactured from Aramid, Polyamid and Wool Fiber and their mixtures. These transfer felts that are widely used in the heat and pressure-aided printing machinery are usually manufactured from aramid fibers. They are also used in the ironing and lamination processes of various fabrics. Laundry felts which are special felts for laundries and which are used in many sectors are manufactured from polyester, aramid and wool fibers and their mixtures. Food sector felts offered for various chemical applications and sizes such as endless weaving and endless weaving biscuit felts are manufactured from wool fibers. Please request information and support for all kinds of industrial felt requirements of yours.

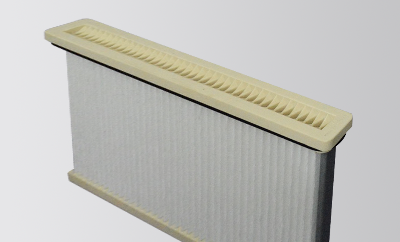

CARTRİDGE FILTERS

Cartridge filters as compact filter elements provide 2-3 times more filtration with their pleated forms when compared with filter bags of same size. They are ideal for applications where the bag size is poses a problem. These type of filters are good alternatives for filtration with their high dust collecting capacities, flexible top blind flanges, endless pleated felts and conformity to jet-pulse shaking. Features and Benefits ■ 2-3 times wider filtration space ■ Longer periods of use ■ High dust collection capacity ■ Simple and quick placement Cartridge filters are available up to lengths of 1,600 mm and sizes which can provide a filter area of 15m2. The filter elements may be installed by clean or unclean gas in accordance with the requirements.

FEATURES AND ADVANTAGES

FEATURES

Filter fabrics: Needled felts, Standard non-woven

Special Applications and features: ePTFE-membrane, anti-static, spark preventive, moisture and oil repellent, micro-impregnated.

IFA classes : L, M, H

Filter classification: DIN EN 779 (For coarse and fine dust)

Filter classification: EN 1882-1 -H13

ADVANTAGES

Advantages of panel/flat filters:

■ Variety in size and shape is available

■ Compact and flat – occupy small space

■ Wide filtration area – High dust overload capacity

■ Rigid frame – efficient dedusting

■ Venturi style header section, separate and wide air flow channels

■ Best operation with Jet-pulse

■ Low pressure difference – low energy consumption

■ Above average operational life – low maintenance costs

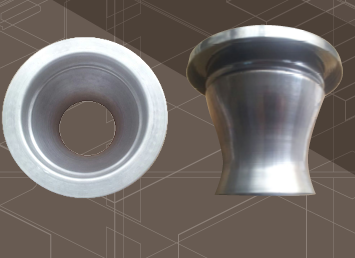

VENTURI, CLAMPS AND VALVES

Filtration is a total process depending on many components. Along with the filter bags and their fabrics which are the last and the most critical part in this process, the filter itself as the operational environment for these and the support cages, venturis, valves and clamps that make up the filter are of same significance. Fiterteks also supports you in the procurement of all the equipment that make up the filter.

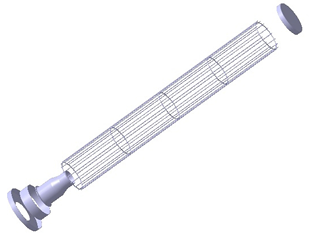

SUPPORT CAGES

The ability of “Jet Pulse” filter bags to provide long term optimum operational performance at the processes they are used is directly related with the “Support Cages” they are supported with. It is highly important that the support cage is positioned in the bag so that enables the efficient removal of the dust from the surface and in a way that it prevents tear that may occur as a result of the mechanical stress on the bag. Fabrics manufactured as “felt” or “woven” require different levels of support for obtaining mechanical durability. Based on the experiences of Filterteks, the following information has been prepared as a guide for the design of cylinder type cages with regard to both types of fabrics. *The recommended cage material depends on the gas conditions. They may be recommended depending on the applications to be used at.

General Recommendations

■ Don’t use cages undergone corrosion

■ Don’t use cages containing skewed, broken/skewed vertical wires and/or rings.

■ Welds should be smooth and burr-free on all surfaces.

■ Bottom cap edges should be bended inwards if possible.

■ Venturies should be connected in a way directing the air in a uniform manner and not contain holes that may lead to localized bag abrasion

■ Minimum single thickness: 3-4 mm

■ Engineering specifications: Length: : +0 – 1⁄4”; Diameter: : +0 – 1⁄32”

■ Ring welds must be behind the vertical wires and must have a smooth surface.

■ Base diameter must not exceed cage wire diameter. It should preferably be 5mm less.

■ In cases where bottom cap is narrower than the cage wire diameter, first horizontal ring must be placed appropriate to the filter bag support (if present).

■ Cage flank and/or panel (plate) support must be placed vertically in the cage in order for the cage to support the bag lengthwise. For the flexible ring header to preserve its impermeability functionality in flexible ring (R/C) systems, it must be designed so that the cage weight can be borne by the panel/plate.

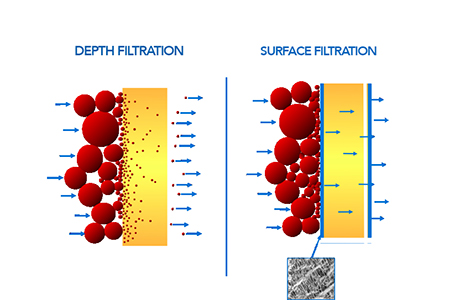

ePTFE Membrane Products

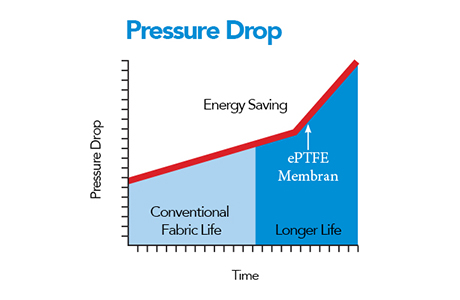

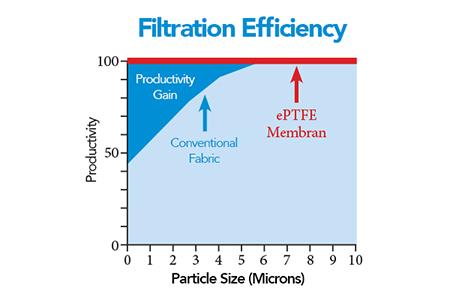

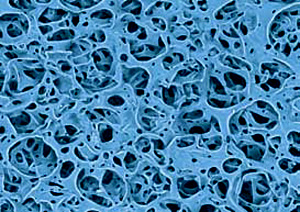

They are made up of 100% PRFE polymer resin. They are chemically inert and thermally stable up to 325 °C. The Membrane contains over 100.000.000 pores per cm2. They are manufactured for the jet pulse, reverse air and cartridge filter dust collection systems that they are applied on and they are bonded thermally woven, non-woven polymer and felt fabrics. - Unique micro structure - Effective pore sizes - High porosity over 100.000.000 pore/cm2 - Two dimensional structure - Water repellent feature - Non-reactive against chemicals - Operating capability -150 and +287 °C The membrane is a surface filtration material which doesn’t require presscake formation before and during the operation and that itself takes on the primary presscake function to start the filtration process. Membranes protect the material integrity of the conveyor fabrics by limiting the presscake formation and preventing dust penetration into the conveyor fabrics. They provide optimum air flow, stable pressure drop and long bag life thanks to these features. Membranes even capable of collecting submicron dusts thanks to their advanced micropore structures, they facilitate a considerable increase in particle collection performance and the establishment of low emission values. As they are derived from PTFE polymer resin and that they limit presscake layer formation, they substantially improve the capacity of dust collection from the surface. Thus, they enable shaking at low pressures, dust emission at low fan power which means energy saving at high levels. - reduced pressure drop - high air flow - high production volume - low energy consumption - energy saving with variable speed fan engine - low pressure air consumption - long bag life

Chemical Applications

Needled felts have many chemical impregnated applications to improve their performance and tp preserve their technical specifications. LR5 This most common standard chemical application characterized with the code “LR5” is designed to prevent water and oil infiltration into felt texture. After this procedure of dipping the felt completely in the polymer compound after the production, every single fiber constituting the felt is covered with a fine layer of polymer. As a result of this, the liquids contact with polymer chemical instead of the felt fibers. By means of this application, the felt is endowed with a permanent resistance to abrasion and effects of water. The procedures may virtually be applied to all kinds of felts. The application has two basic benefits. The felt itself becomes water repellent which prevents moisture penetration into the conveyor texture. Secondly, the moisture in the dust which is likely from the fuel, oil or water is repelled thus preventing any possible bag occlusion in case of such conditions. CR1 Filterteks implicates a one step ahead, more advanced version of the “LR5” application which is characterized with the code “CR1”. The improvement of the filter fabric’s resistance to chemical attacks that may arise as a result of the gas flow is targeted along with a more advanced water and oil repellent feature. The improvement of oil and water repelling functionality is ensured after the application and in addition to this, the deferment of the degradation of the functionalities of the filter fabric will be procured resulting in a longer bag life. Just as in the “LR5” application, following this procedure of complete dipping of the felt in the polymer compound after production, every single fiber constituting the felt is covered with a fine layer of fluorocarbon. As a result of this, the liquids contact with polymer chemicals instead of the felt fibers. Its distinction is that the polymer layer around the fiber is stronger and more effective due to a more detailed and finer application. As similar chemicals are used at the “LR5” and “CR1” applications, they give similar anti-static responses (“LR5” 25 cm, “CR1” 30cm). The plus performance of the “CR1” application with the Hydro-static features is acquired from the modification of the surface energy obtained, depending on the thickness and the coating method of the fiber covered with polymer. DR7 The application is developed in order to assist removing the adhesive dust from the felt surface. Many types of dusts have adhesive features in their nature that causes the felt to occlude by infiltration through the surface of the felt. The application reduces this tendency and helps the dust to be easily removed from the surface. It can be applied to many filtration felts. DR8 The application is developed in order to assist removing the adhesive dust from the felt surface. Many types of dusts have adhesive features in their nature that causes the felt to occlude by infiltration through the surface of the felt. The application reduces this tendency and helps the dust to be easily removed from the surface. It can be applied to many filtration felts. MW & MW2 These applications developed to reduce the filter emission levels are carried out by applying polymer foam to the surface of the felt. MW is genereally used at shaking system filters whereas MW2 is customized for jet-pulse systems. There are mainly applied to polyester felts.

Anti-static Feature

Many dust are inclined to produce electricity. This static electric poses risks of fire and explosion as they accumulate intensively at the filtration systems due to the insulating features of the filter fabrics. The problem of static electrification of the filter bags during the filtration of dusts such as coal/dough is important in terms of both work safety and the performance of the bags. Beyond being a trouble complicating the process of removing the dust from the filter bag and obstructing product flow, static electrification may act as a source of ignition in cases where the gas media is explosive. There is accumulated electrical energy at the place where static electrification occurs. If the components constituting the filter system (incl. filter bags) are poor conductors, the accumulating static electric tends to stay at the place of formation. If the dust and the filter bags are charged negative, it sticks to the surface of the dust filter bag and cannot be removed by shaking. And thus the performance of the filter bag are affected. There is CO, a gas ready to explode, present in the filters collecting coal dust and thus posing a threat of fire or explosion in case of spark to occur due to the static electrification. The filter felts manufactured from mixtures based on the triboelectric series of standard fibers such as Polyester, Acrilic and Polyamid (PES, PAC, PA) don’t possess the anti-static functionalities as described in the above criteria because non-conductive fibers don’t conduct the static electric to the ground in sufficient amounts and speed. In addition, they don’t prevent the formation of static pools. The static electric is generated as a result of the dust particles’ collision or frictional movements with themselves or with the surface of the equipment. The settlement of dust particles on insulating surfaces forms static electric charged areas known as static pools. The static electric problem arising in this manner can be prevented by conducting the static electric to the ground line with the filter bag serving as a conductor. Anti-static filter felts have the capability to conduct static electric along their surfaces and along their depths by means of the conductor fibers and/or inner textures which they are comprised of. The material widely used is Stainless Steel Grate due to their advanced chemical and thermal resistance, applicability to all fibers and high conductivity values. In EU and the USA, it is stipulated for the filter fabrics used in the filtration systems carrying the risk of static electric to have a surface resistance of 108 °C or below values. The electricity resistance in textile products are tested in accordance with the DIN53.345-EN13.463/1 values.

Product Choice

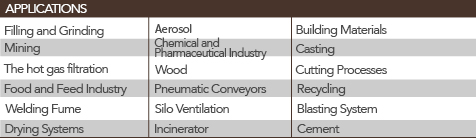

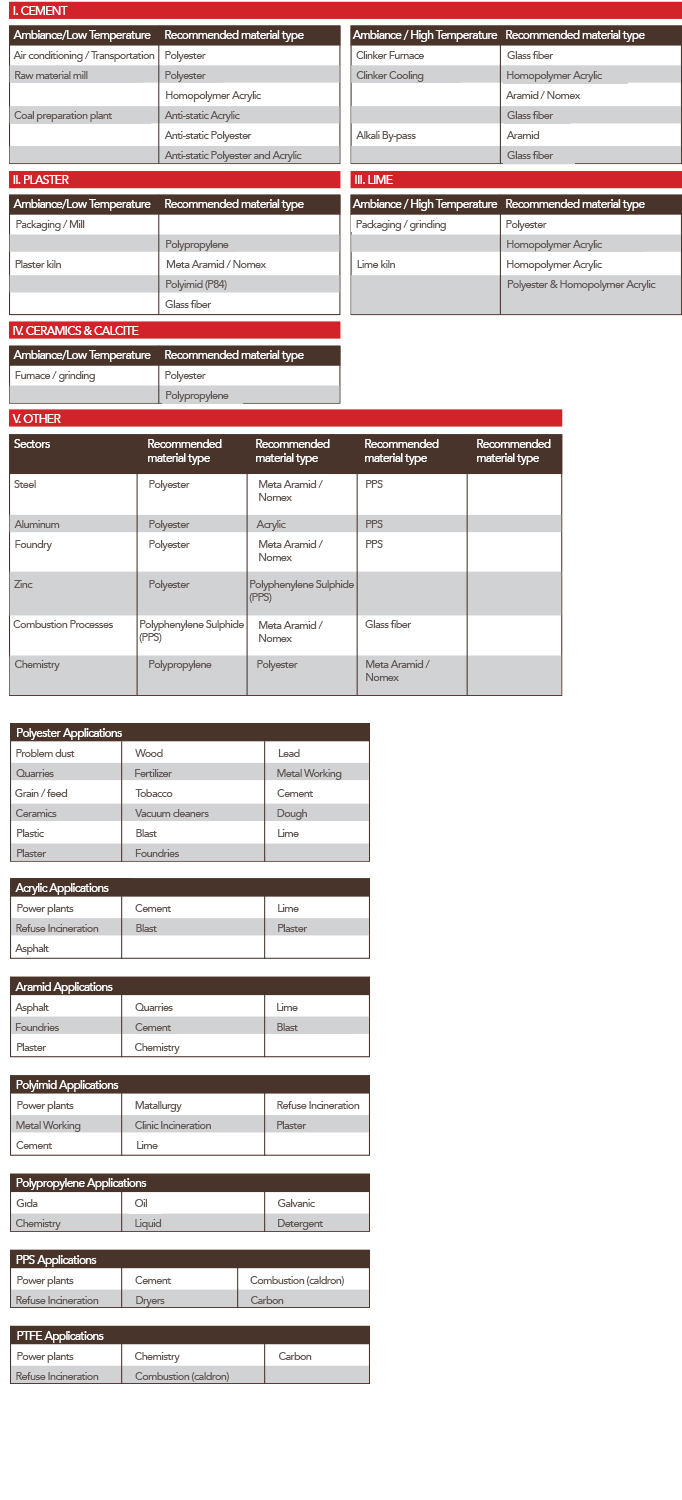

Most of the air borne dust is generated during the excavation and mining procedures carried out to extract raw materials, and the pulverization, combustion processes, grinding, storage and packaging for processing the raw material. The emissions formed can be controlled by sealed systems which the processed air is directed to the filter bags for dust filtration. The dust collected can either be used to proceed with the manufacturing processes or can be utilized to be mixed with the other products or to be stocked as waste. The dust in the filtration systems consisting of filter bags is separated from the air flow which itself is carried in by the method of collecting the dust particles on the surface during the permeation of the charged air flow through porous materials. Filters may consist of small amounts or thousands of meters of fabrics providing efficient dust separation by acting as a separation barrier. Therefore, one of the most important factors among many to be considered is the ability of the selected filter material to permit the gas pass while holding the solid particles. Dust emissions originating from Furnace and Mills may have an effect on a great scale due to use of tall outlet chimneys. As this effect may cause health problems, it may also mean loss of products. Thus the filter bags used in the filtration systems must succeed in meeting the restraining environmental rules. The desired environmental emission values and particle collection capabilities can only be obtained with efficient and effective filter bags. Factors defining the choice of filter bags: Temperature; The most important factor, regardless of the gas distribution, is doubtlessly the temperature amongst the important factors to take into consideration while choosing a bag. Filtration applications are divided into two sub-groups: Low temperature filtration: means processes such as mill, grinding, mixing and packaging which operate at temperatures close to the ambient temperature. High temperature filtration: means applications where there are dryers, furnaces and caldrons which heat is induced or which they are a part of the process. Gases and Chemicals; The capability of filter fabrics to resist deformation and abrasion against acids, alkali, solvents and oxidants at operation temperature levels must be taken into consideration. Moisture; The hydrolysis resistance of the filter bags at the anticipated temperature and moisture levels should be evaluated. Dimensional Stability; The Filter fabric’s resistance to contraction and stretch forces at the expected temperature and gas conditions should be taken into consideration. Type of filter unit; Cleaning method and pressure, the structure of the filter bag and the cage design should be taken into consideration separately. For reinforcement and improvement; Available application background should be investigated.

Sectors

Performance Tests

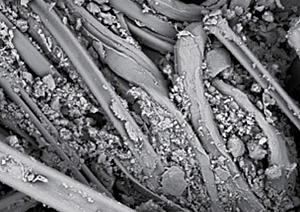

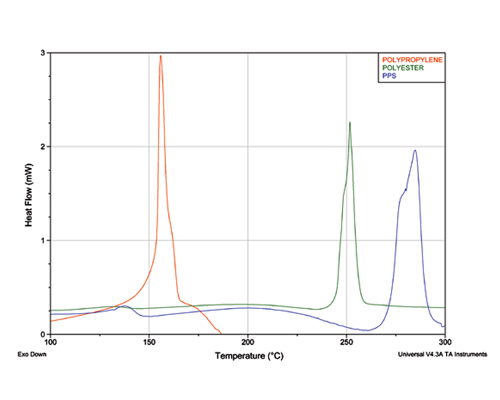

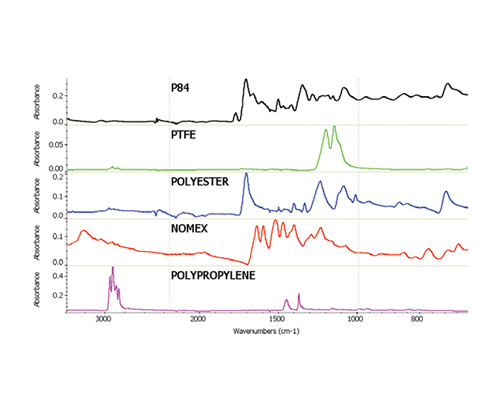

As Filterteks, we believe that the solutions special for your establishments can be achieved with the analytical assessment of the data acquired via technical observations. In this context, we analyze and report the data obtained both by versatile tests of filtration products and the assessments of technical studies onsite by our solution partners and our experience. Testing studies are carried out together with the laboratory facilities within our organization and the technical facilities of our domestic and foreign solution partners. Products not tested with the available testing devices or products that have operated in systems are assessed in terms of weight, air permeability, tear and tensile strengths. Every fiber and dust particle can be monitored with scanning electron microscope. Thus it provides us the opportunity to facilitate thousand times focused zooming for the observation of the filter medium. Assessment of these medium sections provide us the opportunity to assess chemical applications, fiber deniers and felt structures. It is possible to record the chemical structure of the fibers, melting point resistances and the rates within the felt and many more fine details with tests methods like “Differential Scanning Calorimetry”, “Fourier Transform Infra-Red Spectroscopy” and “’VDIRR”. Please fill out and send the form for your material testing requests and send your sample to our İstanbul office.

ABOUTAbout

TAİLORED SOLUTİONS..

Filterteks, Filtre ve Keçe Sanayi A.Ş.

Filterteks, Filtre ve Keçe Sanayi A.Ş. provides special solutions for you with effective services in the field of Industrial Textile and Filtration. In order to provide services to you upon every aspect of filtration, we operate in our headquarter office in İstanbul Güngören and in our factory set on a 14,000m2 area with 5000m2 indoor section. We have cooperated with the leading companies of the world in order to serve our 35 years of experience of filtration effectively. We present a wide range of products consisting of our own productions and imported products together with traditional and high-tech products. With ever changing and evolving technologies, filtration includes both eco-friendly and efficiency enhancing applications. We are honored to work with you as your solution partner providing custom solutions when you encounter problems.About

NEWSNews

OUR NEWS

01/05/2014 Filterteks supports sports

Filterteks A.Ş. wishes good luck and an entertaining match to the volleyball players of Oyak Adana Çimento (cement) plant…

01/01/2014 Fiterteks Liquid Filtration

Filterteks A.Ş. is expanding its liquid filtration product range and capacity with new machinery investments and increased personnel. Filterteks A.Ş. is providing custom solutions for the continuous requirements of the mineral, marble, ceramics and refinement sectors such as filter press, Larox belt and belt press with its own production fabrics and international connections. All CE certified products are at your service.

Please contact Orhan Selçuk Doğancan from the technical support department from the address orhan@filterteks.com or via the phone +905544968192 for further information…

01/01/2014 Filterteks Air Slide Fabrics

Filterteks is enhancing its Air Slide fabrics production capacity and new machinery investments. Filterteks A.Ş. has been providing its own production air slide fabrics to the Turkish market for over 35 years and is proud to export proprietary products as Polyester, Meta Aramid and Para Aramid. For further information, please contact us through our technical support department or from the address filterteks@filterteks.com...

01/01/2014 Filterteks Cartridge Filters

Filterteks A.Ş. is adding TÜV certified custom, high-quality cartridge filters to its product range by means of its international partners. We introduce you a special quality scale of compact filters favored by many sectors due to their small space requirements, advanced dust collection capacity and their easy use.

11/10/2013 AUCBM Filterteks Middle East

Filterteks A.Ş. representatives are going to attend to The 18th Arab Union for Cement and Building Materials (AUCBM) Conference and Exhibition at the address of Bin Talal Convention Centre in Jordan (King Hussein Bin Talal Convention Centre Dead Sea, Jordan) between the dates of 11/11/2013 and 13/11/2013.

The exhibition which takes place every year is one of the significant meeting points of construction and cement sector.

01/10/2013 TÇMB Technical Seminar Antalya Turkey

Filterteks A.Ş. will be at your disposal in the 6th stand of 12th TÇMB International Technical Seminar and Exhibition to be held in Gloria Golf Resort hotel between 08/10/2013 and 10/10/2013. We will take our place to be of assistance to you with our products and expertise at the most significant meeting of the Turkish cement sector which is held once in every two years. Mr. Callum Baxendale, technical manager of Andrew Webron Ltd. - whose products we distribute in Turkey - is going to join us as well.

Our Marketing manager Mustafa Şabanoğlu and Technical Marketing representative Abdullah Göğebakan await your precious visits. To contact, please note: E-mail: mustafa@filterteks.com Phone: +905558541806

01/06/2013 Techtextile Filterteks

Filterteks A.Ş. representatives are going to attend Techtextile 2013 exhibition to be held in Frankfurt between 11/06/2013 and 13/06/2013. The exhibition which is held once in two years is amongst the limited meetings in the world to keep up with the technical textile products and the innovations in the sector.

Our Marketing manager Mustafa Şabanoğlu will be present at the fair to meet our precious customers. To contact him, please note: E-mail: mustafa@filterteks.com Phone: +905558541806

CONTACTContact

CONTACT US

CONTACT US

Head Office

ADDRESS: Sanayi Mahallesi Çağlayan Sokak 19/1 34165 - Güngören / İstanbul

PHONE: +90 (212) 554 29 04 pbx +90 (212) 554 29 06 fax

E-MAIL:

filterteks@filterteks.com

Factory

ADDRESS:

Orta Öçekli San. Böl. Yavuz Selim Mah.

Mehmetçik Cad. No: 4 37300 - Tosya / Kastamonu

PHONE: +90 (366) 313 79 61 pbx +90 (366) 313 82 73 fax

E_MAIL:

filterteks@filterteks.com